Unpacking the Latest In-house Logistics Exhibition Insights of Spring 2023

In this article, we collected our insights concerning in-house logistics workstations.

Exploring the Future of Logistics: Cutting-Edge Technology Showcased

At the exhibitions, we saw a wide range of futuristic technology designed to streamline the entire logistics process. From automated warehouses powered by AI to autonomous delivery vehicles, everything is being designed to work seamlessly together to ensure the smooth and efficient movement of goods.

We were impressed by the possibilities that these advancements could offer and can't wait to see how their implementation will grow over the next few years.

The Value of Manual Work in the Age of Automation

As mentioned, the adoption of automation has garnered immense attention in the exhibitions held this spring. The cobots and conveyers featured in these expos were impressive, showcasing the latest technological advancements.

Joel Stillson, a regional sales manager in the US, has recognised the importance of manual labour in the age of technology:

- "It is important to note that manual work still continues to hold its relevance in the industry. Despite not being as glamorous as the new and shiny technology, companies are still invested in improving the manual aspect of the work at hand. Companies rely on our holistic expertise in creating ergonomic, smooth workstations that support the workflow."

The Importance of Designing Integrative Workstations in the In-House Logistics Sector

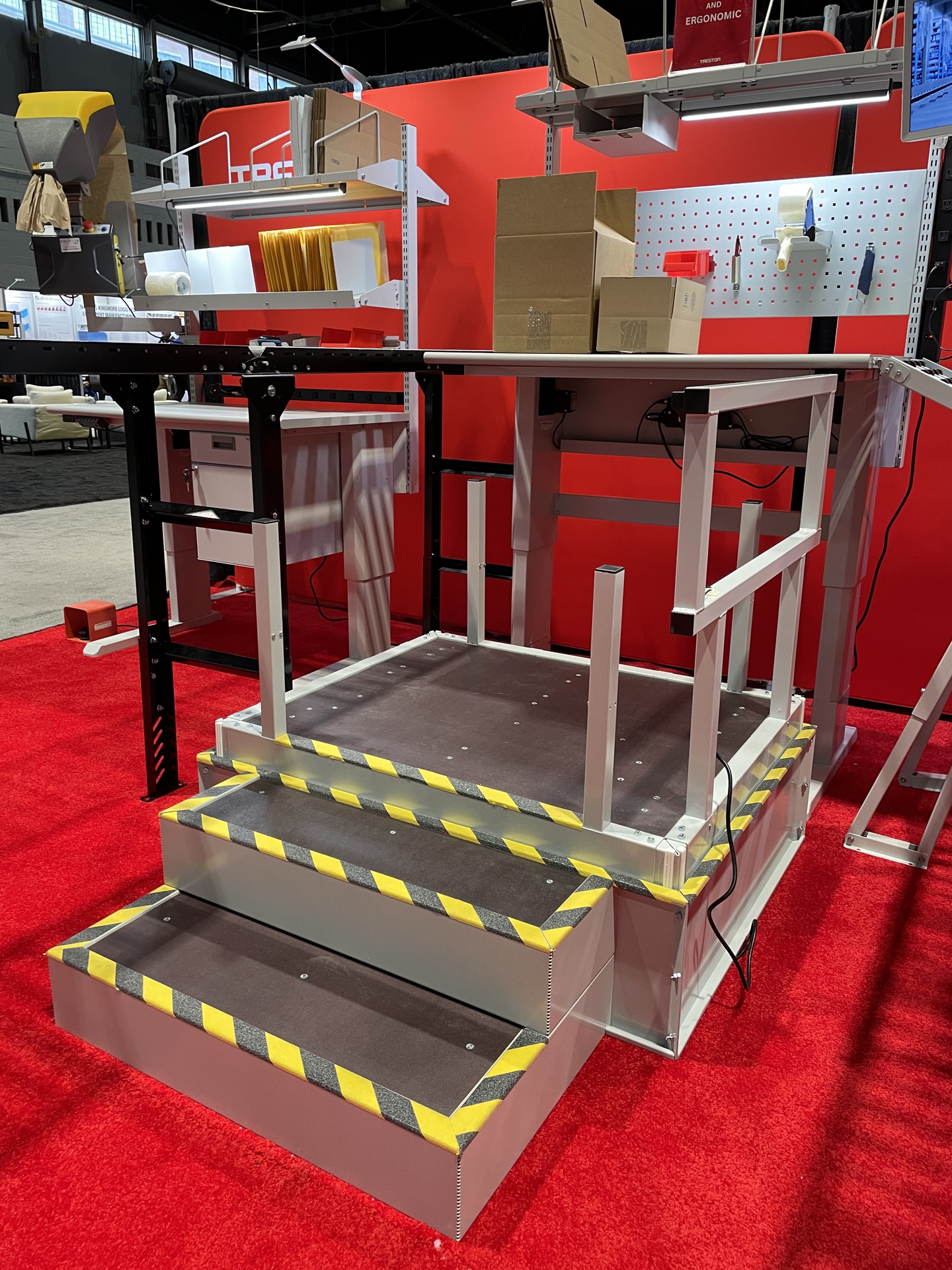

When it comes to designing workbenches in the in-house logistics sector, knowing the entire process is crucial. Manual workstations must be designed in a way that allows for integration with automated systems. During the exhibitions in which we took part, we noticed the importance of integrating manual workstations with automated lines.

In each exhibition, we were glad to see that visitors were impressed by the possibility of attaching workbenches to conveyer lines, for example, through the use of ramps. This highlights the need for well-designed workstations that can keep up with the demands of modern, automated logistics systems.

Ergonomic Improvements in the Workplace: A Growing Trend Among Employers and Employees

Among other things, Joel Stillson has noticed the importance of constantly growing the need for ergonomic workstations in the in-house logistics sector:

- “During the exhibitions, we noticed that the trend of improving ergonomics still continues to grow. Many individual employees expressed that their current packing stations and workstations are too standardised, lacking necessary individual adjustments such as height or reachability."

In the in-house logistics sector, it is typical to use the same workbench for multiple employees, which often neglects the ergonomic needs of each individual. Stillson emphasises that competition among the workforce is directly correlated with the working conditions provided:

- “Employers are now realising that ergonomic improvements not only benefit the health of their employees, but also reduce employee turnover. Many companies have observed that employees will switch jobs if their current employer does not offer a job that supports healthy work practices.

Modular Workbenches: Enhancing Productivity and Adaptability in Evolving Workspaces

As workspaces continue to evolve, there is an increasingly apparent demand for workbenches that offer modularity and flexibility to support the workflow. By optimising the workbench for specific tasks, productivity can be greatly enhanced.

However, in order to continuously improve the workflow in processes, workbenches must be capable of being modified more extensively than simply adding a few standardised components. This need for adaptability is key to staying ahead of the ever-changing demands of modern workplaces.

At Treston, we are ready to offer, in addition to the modular workbenches with an excessive number of accessories, many different kinds of customised solutions.

Read more about lifting platforms and other customised solutions for in-house logistics.

Did you spot us at these exhibitions in the spring of 2023?

- Promat, Chicago.

- SITL Transport and Logistics Innovation Week, Paris.

- Logimat, Stuttgart.