Understanding ESD powder coating in ESD workstations

What is ESD powder coating?

ESD coated paint, also known as ESD powder coating, is a specialized finish applied to surfaces to provide protection against electrostatic discharge. This coating is formulated with conductive or dissipative materials, such as carbon black or carbon fibers, to create a path for the controlled movement of electrical charges.

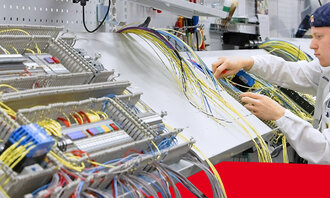

ESD coated paint is commonly used in industrial settings, especially on workstations and equipment, to prevent the buildup of static electricity that could potentially damage sensitive electronic components.

The key feature of ESD powder coating is its ability to facilitate the controlled dissipation of electrical charges. When a static charge is present on the coated surface, the conductive or dissipative materials within the coating provide a pathway for the charge to flow safely to the ground. This prevents the accumulation of high voltages that could potentially damage nearby electronic components.

Treston ESD workstations have a semi conductive paint film

All Treston ESD compatible workstations are light grey (RAL 7035) in color and have a semi conductive paint film. The coating is based on epoxy and polyester resin and it is developed especially for the ESD-protected areas (EPAs).

The semi-conductive paint film has excellent mechanical properties, i.e. abrasion and impact resistance and elasticity. It does not scratch easily and it withstands action by chemicals, greases, and solvents.

The advantages of using ESD powder-coated workbenches

ESD coated steel workbenches offer several advantages over ESD mats or laminate on non-ESD benches. Here are some of the benefits:

- ESD Protection

ESD powder-coated workbenches are designed to provide complete ESD protection across the workstation. The ESD Powder coating creates a controlled path for static charge dissipation. This applies to all parts of the workstation, from bench frame to shelving and bin rails. - Durability and user-friendliness

Compared to the special ESD mats or ESD laminate table tops on regular workbenches, the ESD powder coating remains effective over time, without the need for frequent replacement.

ESD powder coated workbenches provide continuous protection without the need for additional ESD mats or frequent repositioning. This minimizes disruption to workflow, ensuring a smoother and more productive operational process.

In addition, ESD Powder coated ESD workbenches are built with ESD protection in mind. They offer a seamless integration of ESD properties, ergonomic design, and structural durability, catering to the unique needs of modern work environments. - Single Grounding Point

With ESD powder-coated benches and accessories, grounding the frame is all that is needed, eliminating the need to ground workstation accessories, such as shelves or bin rails.

All Treston products are available in ESD versions

All our industrial workstations are available in ESD-safe versions. In addition to workbenches, we also supply industrial, ESD-safe trolleys, shelves, cabinets, chairs, lights and accessories.

Did you know? Ergonomic Concept Workbench, doesn't require wiring

Treston's ESD Concept bench offers a unique advantage for ESD protection. When placed on an ESD floor, it doesn't require additional ground wiring. The entire structure, including the ESD table top, frame, legs, and leveling glides, is conductive. This creates a continuous conductive "chain" to the floor.

For example, in the ergonomic Concept workbenches motor, conductive plastic slides inside the leg ensure electrical connection between the upper and lower parts of the leg. This design makes sure the table and ESD floor have the same electrical potential, so separate wiring is not needed.

Design your own ESD workbench

Try out the Treston 3D configurator.