Lean is a philosophy and an operating model that focuses on everything that adds value for the customer and eliminates what does not. The goal is to ensure that every activity contributes to value creation and that all processes are streamlined for maximum efficiency.

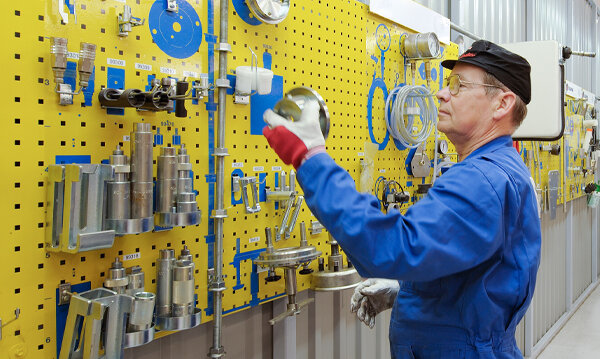

The foundation of Lean lies in recognising and eliminating waste — whether in materials, motion, or time. For example, moving goods back and forth unnecessarily in production consumes time and resources without adding value.

Lean principles help companies:

- Optimise the flow of materials and work.

- Improve quality and efficiency.

- Create safer, more ergonomic working environments.

- Continuously develop processes for long-term improvement.