FAQ's shortly answered

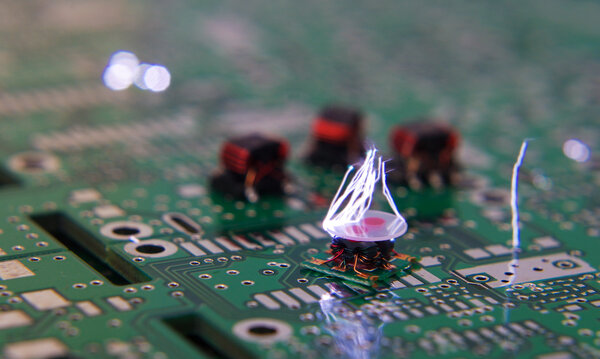

What is ESD and why is it a business risk?

ESD is a sudden discharge between charged objects. It can cause immediate (fatal) or hidden (latent) failures that surface months later, impacting quality, returns, and brand trust.

How low can damaging voltages be?

Common components are damaged at 100–200 V, while the most sophisticated can be affected at just 5–10 V—well below human perception.

What standards should be followed?

Use IEC 61340-5-1:2020 or ANSI/ESD S20.20:2021 for defining what to measure, how to test, and acceptable ranges. Measure in the real environment, not only in a lab.

What belongs in an ESD control plan?

Component sensitivity, acceptable voltage/resistance ranges, grounding methods (including CPG), handling/storage/packing workflows, cleaning/maintenance schedules, and training. Review and update regularly.

Flooring or mats, how to choose the correct one?

For small areas, grounded ESD mats are practical; for large/new facilities, consider a cast ESD floor. Always ground to a common point ground (CPG) and clearly mark EPAs.

Which furniture needs to be ESD-protected?

Any furniture near sensitive components, including workbenches, trolleys, chairs, and accessories (shelves, drawers, bins). Some workbenches ground through ESD floors; others must be wired to CPG - remember to test regularly.

Are wrist straps really necessary?

Yes. They’re the most reliable personal grounding method - especially when chairs are in use. Jackets/footwear add protection but don’t replace wrist straps.

How often should ESD furniture be measured?

Follow your control plan: document surface resistance, grounding, footwear/clothing tests, and cleaning. If values rise, re-check cleaning and that you’re testing the right components.

What about movement and material flow?

Every transfer increases risk. Store parts in ESD packaging/bins, minimize bench-to-bench moves, and use ESD-protected trolleys and packing stations.

Protect your products - start here:

Download the Free E-book (PDF)